Popular Searches:foot scanner | 3D scanner | 3D Printer | Design Software |

Tel :0755-86131192 86180201

Fax :0755-86180213

E-mail: [email protected]

Website: gift0755.cn

Address: 3A05, Minzhi Chamber of Commerce Building, Minzhi Avenue, Longhua District, Shenzhen

Are you here: Home > News > Industry NewsIndustry News

The Principle of Insole Production Using Insole Engraving Machines and Foot 3D Scanners

Time:2025-01-10 14:29:26Source:深圳市精易迅科技有限公司Views:15

As personalized customization becomes increasingly prominent in the healthcare field, the combination of insole engraving machines and foot 3D scanners has emerged as a vital technological approach for producing custom corrective insoles. These devices, with their high precision and efficiency, provide scientific support for foot health. The following sections elaborate on their working principles and specific applications in the insole production process.

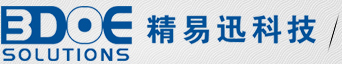

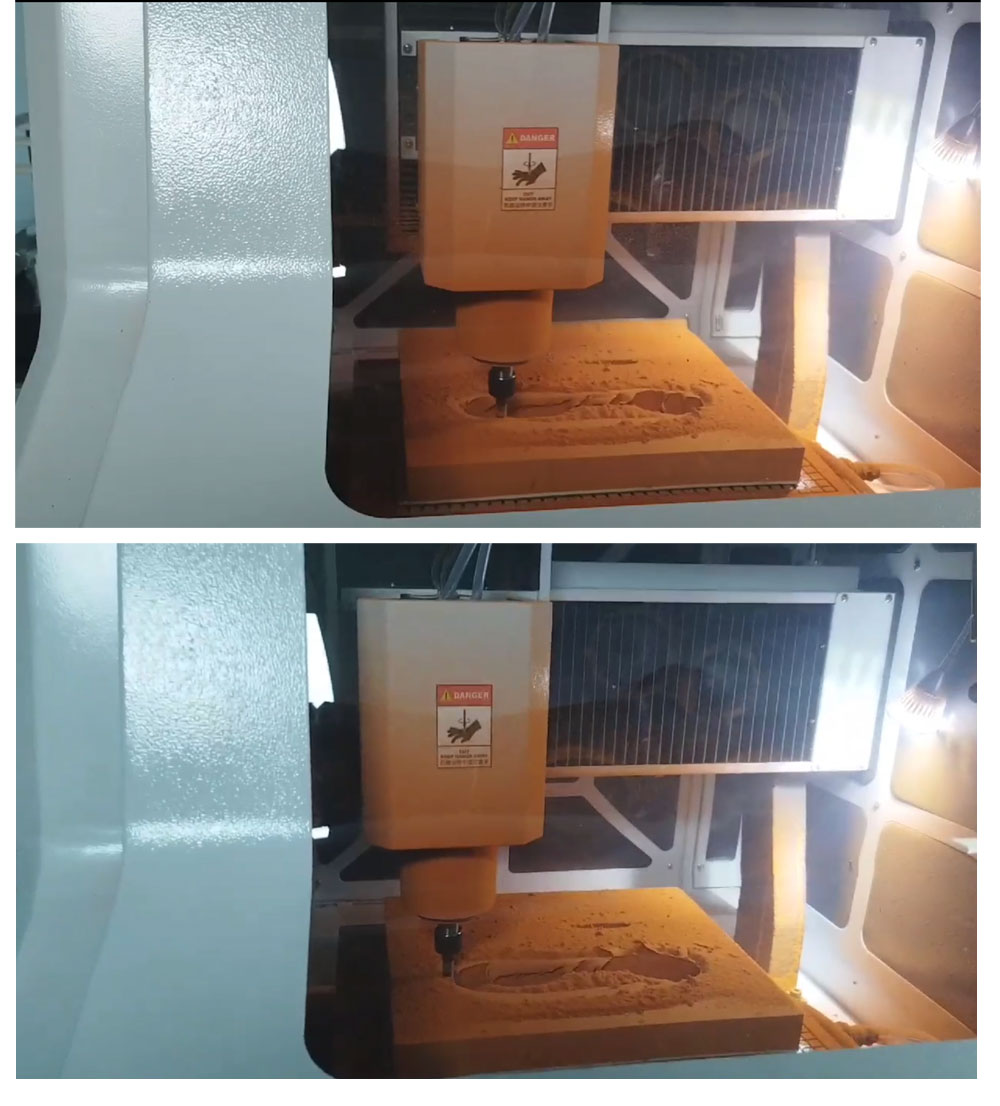

Insole Engraving Machine

1. Working Principle of the Foot 3D Scanner

The primary function of a foot 3D scanner is to collect three-dimensional data about the foot, including foot shape, arch height, toe length, and distribution. This information forms the foundation for custom insole production and is achieved through the following principles:

Optical Scanning

Foot 3D scanners widely adopt optical scanning technologies such as structured light and laser scanning. These techniques project light beams onto the foot and capture reflected light using cameras to generate a 3D model of the foot's surface.

- Structured Light Scanning: The device projects striped light beams, and the deformations of the light on the foot surface are calculated to create 3D data.

- Laser Scanning: A laser beam scans the foot point by point to capture high-precision 3D information, making it suitable for complex foot structures.

Data Processing and Modeling

The raw data captured by the scanner undergoes algorithmic processing to generate a 3D model of the foot. This process involves multiple calibrations to ensure accuracy and integrity. By analyzing the model, special foot structures, such as high arches or flat feet, can be identified, providing a scientific basis for insole design.

2. Working Principle of the Insole Engraving Machine

The insole engraving machine converts the designed insole model into a physical product by utilizing CNC (Computer Numerical Control) technology to achieve high-precision results. Its specific working principles include the following steps:

Digital Design Conversion

Data obtained from the 3D scanner is processed through specialized software to create a digital design model of the insole. This model includes information on the insole's shape, thickness distribution, and specific support areas.

CNC Engraving Technology

The insole engraving machine uses CNC technology to precisely cut materials according to the design model. The process includes:

- Path Planning: Calculating the engraving path based on the model to ensure precise execution of the design.

- Multi-Axis Coordination: Modern engraving machines often support multi-axis coordination (e.g., three-axis or five-axis) to efficiently process complex insole shapes, particularly for custom insoles with irregular curves.

Material Processing

The engraving machine processes materials such as EVA (ethylene-vinyl acetate) or polyurethane, which are soft yet sufficiently durable. These materials maintain the design's accuracy during the machining process without significant deformation.

Finishing and Post-Processing

After engraving, insoles may undergo finishing steps such as polishing and trimming to ensure a smooth surface and meet usability standards. Additional support layers or cushioning pads may be added for specific foot needs.

3. Integrated Workflow of the Two Devices

The combination of foot 3D scanners and insole engraving machines creates a complete workflow for custom insole production:

- Data Collection: Capture detailed foot data using a 3D scanner.

- Model Design: Use specialized software to generate an insole design, simulating mechanics and shape matching.

- Engraving and Processing: Input the design model into the engraving machine, cutting insole materials to precise dimensions.

- Testing and Adjustment: After preliminary processing, test the insoles for fit and make adjustments if necessary.

4. Advantages and Future Prospects

Insoles produced using this method offer high levels of personalization, precision, and quick response times. In the future, with advancements in artificial intelligence and machine learning algorithms, insole design and processing technologies will continue to improve, allowing corrective insoles to better meet foot health requirements.

Through the above analysis, it is evident that the combination of foot 3D scanners and insole engraving machines is a crucial component of personalized insole production technology. Their high precision and efficiency are gradually transforming traditional practices in the foot care industry.